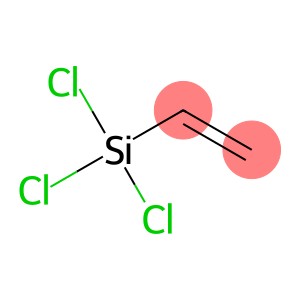

Trichlorovinylsilane(CAS#75-94-5 )

| Risk Codes | R11 – Highly Flammable R14 – Reacts violently with water R20/21/22 – Harmful by inhalation, in contact with skin and if swallowed. R34 – Causes burns R20 – Harmful by inhalation R37 – Irritating to the respiratory system R35 – Causes severe burns |

| Safety Description | S16 – Keep away from sources of ignition. S26 – In case of contact with eyes, rinse immediately with plenty of water and seek medical advice. S36/37/39 – Wear suitable protective clothing, gloves and eye/face protection. S45 – In case of accident or if you feel unwell, seek medical advice immediately (show the label whenever possible.) S8 – Keep container dry. S30 – Never add water to this product. S29 – Do not empty into drains. |

| UN IDs | UN 1305 3/PG 1 |

| WGK Germany | 1 |

| RTECS | VV6125000 |

| FLUKA BRAND F CODES | 21 |

| TSCA | Yes |

| HS Code | 29319090 |

| Hazard Class | 3 |

| Packing Group | I |

| Toxicity | LD50 oral in rat: 1280mg/kg |

Introduction

Vinyl trichlorosilane is an organosilicon compound. It is a colorless liquid with a pungent odor at room temperature. The following is an introduction to the properties, uses, preparation methods and safety information of vinyl trichlorosilane:

Quality:

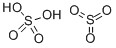

3. Vinyl trichlorosilane can be oxidized to form vinyl silica.

Use:

1. Vinyl trichlorosilane is an important intermediate in organic synthesis and can be used for the synthesis of organosilicon compounds and organosilicon materials.

2. It can be used as a modifier for rubber and plastics to improve their aging resistance and weather resistance.

3. Vinyl trichlorosilane can be used in the manufacture of products such as coatings, sealants, and ceramics.

Method:

Vinyl trichlorosilane can be obtained by the reaction of ethylene and silicon chloride under general conditions of 0-5 degrees Celsius, and the reaction is accelerated by the use of catalysts such as copper catalysts.

Safety Information:

1. Vinyl trichlorosilane is irritating and corrosive and should be avoided in direct contact with the skin and eyes.

2. Personal protective equipment such as protective gloves, goggles and protective clothing should be worn during operation.

3. When stored and used, it should be kept away from ignition sources and oxidants to prevent fire or explosion.

4. When the material leaks, it should be removed quickly to avoid entering the drainage system.